This question is posted by the ecoinvent team on behalf of Romain Sacchi.

The format of the ecoinvent forum does not allow to upload better quality pictures, if better resolution is needed, please contact the author of the figures.

Hello,

I have a question regarding the role of steel scrap disposal in the steel production in the cut-off version of ecoinvent.

I was not able to obtain an answer form the V2 reports, neither from ecoinvent.

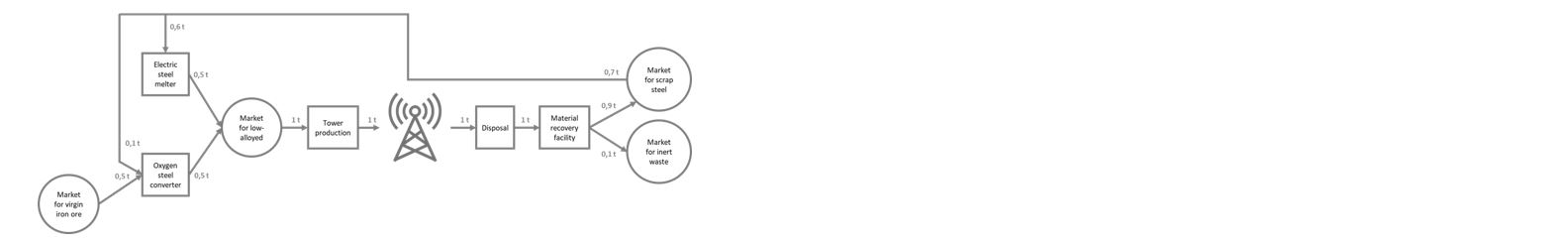

For the case, we would take the very simple example of the production of a 1 ton steel-made tower, without losses.

Ideally, assuming a system that recycles 90% of the post-consumer steel scrap (that’s about the assumed European conditions), I would naively expect such model representation.

But, much to my surprise, the real underlying modelling in the cut-off version of ecoinvent seems to be rather like what follows.

So, do I interpret correctly the fact that we have a system that draws 0,7t of iron scrap and only sends back 0,005t on the market?

And if so, does it means that the recycling rate is in fact rather close to 0,5% instead of 90%? The issue is that I cannot really find a documentation supporting the split figures in the market for scrap steel.

Thank you for your help.

Best regards,

Romain Sacchi